DIY Curved Rulers

A quick one day project becomes a multi-day experiment.

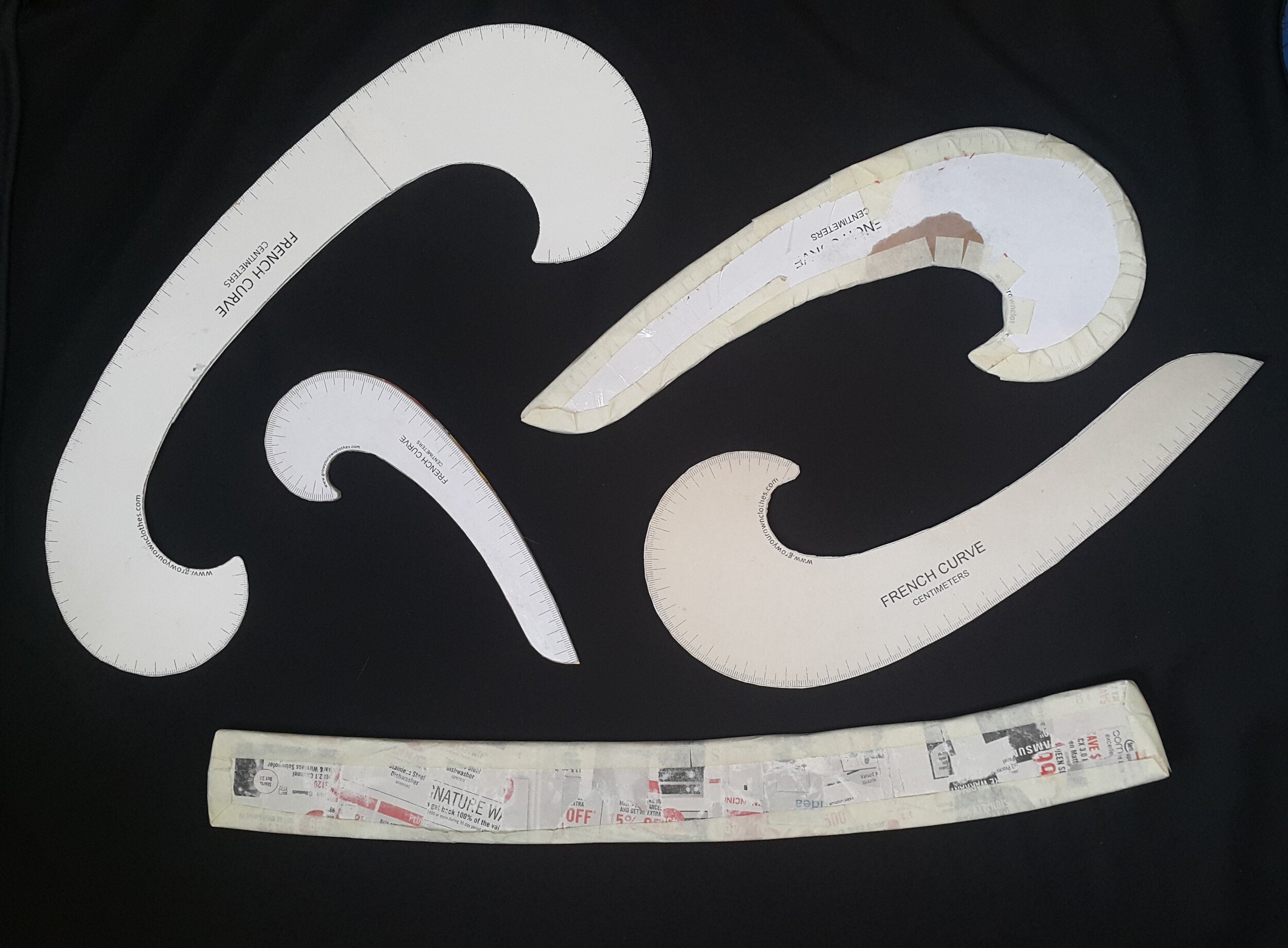

When I decided to make myself a set of curved rulers, I just finished a rather intensive quilt project and thought this would be an easy, one-day activity. I also had on hand a large cardboard box from a recent delivery that I could use. It turns out that this was not as simple an endeavour as I thought and it ended up taking me more time than I expected. I set aside a day to make (and film me making) one hip curve and one French curve and ended up investing days (read: too much time) making a workable ruler but not after trying a couple of other methods and materials.

The way this all unfolded, with me asking questions and trying out new ideas, reminded me a lot of a scientific experiment. This project entry is written like a scientific lab report because this process of me setting out to make two rulers and then ended up making three functional curved rulers and four that are ineffective, some completely fails. The video I made for this project details the making-of process and frames it as a scientific inquiry. This was my first time using Adobe After Effects. I also added captions to this video too. As much as this video is about rulers, this really was a massive exercise in video production and editing.

A Scientific Inquiry: Determining the Best Materials for DIY Garment Rulers

Introduction

When I committed to my long-term goal of making clothes, I thought that making my own curved rulers out of corrugated cardboard would be a quick and easy way to add an important tool to my collection. I didn’t have an immediate need for either a hip curve or a french curve but I anticipated I would eventually and wanted to have something on hand. I also figured that I could craft these rulers with recycled materials already on-hand, thus eliminating my need to purchase anything, which is an economical and environmental benefit.

Other pattern designers and sewists have constructed their own rulers and shared their methods through blog posts and videos, many using a combination of tape and various materials. Some instructional posts have suggested: heavy paper or paperboard; cardboard (thickness unspecified); and event wood. Using metric ruler templates created by Leila from www.growyourownclothes.com, I wanted to try to construct a ruler with a similar thickness to the plastic rulers I already have while still drawing a smooth, useful curve. Ultimately, creating these rulers took me longer than I planned because I ran into some difficulty trying to use a thicker corrugated cardboard. Some troubleshooting led me to test several different materials and methods, ultimately finding a type of cardboard and method of preparation that resulted in a smooth curve.

Materials and Method

The following materials were used to assemble the bases of the curved rulers. The initial size does not matter, as long as the templates fit, ideally with no bends or joins in the material.

Corrugated cardboard box

Cereal box cardboard

Cardstock

Curved ruler templates printed on 20lb paper

The following materials were used to secure the template to the base:

Scotch tape

White glue

The following materials were used to finish the edges of the

Masking tape

Starch mix (1/2 cup water, 1 tablespoon flour, 1 tablespoon cornstarch)

Newspaper

The following equipment was used:

Straight edge (or ruler)

Scissors (for cutting cardboard and paper)

Bowl (for starch mix)

Spoon (for mixing)

Scrap pieces of paper were used to apply glue

Paper clips and/or binder clips

Cutting mat (optional)

Utility knife (optional)

Rotary cutter (optional)

Pen + surface for tracing

A measuring tape (for examining results)

The base and edge materials required for this experiment were found at home. The rulers will be prepared in the combinations listed in Table 1.

Table 1: Ruler Preparations, including template type, base material used, type of adhesive, and how the edges were finished.

The first step in constructing the rulers is to prepare the base materials. For the corrugated cardboard bases, the ruler templates were printed onto paper (a standard 20 lb weight). The hip curve template was printed in two pieces and needed to be assembled together. The edges of the ruler, indicated by the black border, were scored with a straight edge and rotary cutter (prepared with a used blade suitable for paper). Three pieces of scotch tape, each about 5cm long, were used to attach the template pieces together. The templates were measured against the cardboard box and it was determined that the flaps of the box were big enough to accommodate one large French curve template and one hip curve template. Pieces of scotch tape were used to affix the template to the cardboard and then a combination of scissors and a utility knife were used to cut the cardboard out. Once the cardboard pieces were cut, a long length of tape was unrolled and the edge of the ruler was placed on the centre of the sticky side. The tape was kept taut, and wrapped around the entire perimeter of the ruler. The overhang of the tape was wrapped around the edges of the ruler and secured to both faces.

The hip curve was eventually finished with papier-mâché and masking tape. Thin strips of newspaper were torn from larger pieces and dipped in the starch solution. The strips were wrapped around the ruler, with the edges butted up against each other as best as possible so as not to overlap. The ruler was left to dry on the edges of a bowl in order to expose as much of the papier-mâché to air as possible. Once it was dry, masking tape was placed along the edge of the ruler, with the overhand being folded over to the flat sides. The masking tape was adhered in pieces because manipulating one continuous piece was difficult.

The cardstock paper was thin enough to be fed through the printer, so the template was printed onto the cardstock directly and then cut out with regular scissors. To mirror the measurements on the other side, the opposite template image was printed on 20lb paper and secured to the cardstock with white glue. A scrap piece of paper, covered in glue, was slipped between the two layers in order to secure them together all the way to the edges.

The thin cardboard could not be fed through the printer directly, so the French curve templates were printed onto 20lb paper. These templates were cut out and then adhered to the thin cardboard with white glue. Again, I slipped glue in between the two layers to ensure that the thin cardboard was firmly secured to the template paper. Once the glue was dry, I attached the two thin cardboard pieces together with white glue. Paper clips and binder clips were used to hold these layers together because they naturally wanted to unfurl.

The template was traced onto the canvas, rather than affixing a template piece paper on it. The canvas was then folded in half and the ruler shape cut out. This created two equal pieces, each stiffened with a different preparation. One piece of canvas was dipped in a starch solution, the other was coated in a thin layer of modge podge. Both rulers were dried flat while resting on small pieces of scrap cardboard to promote air flow.

Results

The corrugated cardboard was difficult to cut with a utility knife. Slowly using scissors to cut the paper and cardboard resulted in smoother edges. Observing just the way the rulers look the final rulers are identifiable and accurate to the original template shapes. Looking more closely at the edges, there are varying degrees of smoothness, depending on the base material and material used (if any) to cover the edges. When the rulers were traced, the resulting lines were of varying degrees of smoothness (See appendix for Figures 1a-d). Every ruler but the hip curve still shows the centimetre markings indicated on the template. Using a straight edge ruler with centimeter markings, the markings on the French curves remained accurate. Note that the precision of the straight edge ruler was not verified.

Table 2: Summary of results from ruler tests, including basic observations and qualitative measurements of the traced line, how easy the ruler is to hold, and how accurate the cm markers are.

Discussion

This experiment set out to replicate the success that other sewists and pattern makers have had constructing their own curved rulers. In addition to this goal, this experiment had two additional aims. The first was to create a thicker ruler, something that was sturdy like a typical plastic ruler. The second goal was to construct these rulers from materials sourced from home. In general, rulers with paper bases and unfinished edges worked best, but the trade-off was a thinner, less stable ruler. The results of this experiment support Leila from Grow Your Own Clothes’ recommendation to use thin cardboard as the base. To achieve the first goal, a thicker ruler, two pieces of thin cardboard were secured together.

Table 3: Final ranking of rulers based on results.

All of the rulers were made from homemade materials. The downside to all of the rulers that were prepared is that they were not clear and clear rulers are incredibly helpful for seeing what’s under the fabric and lining the edge of your ruler up accordingly. Designing a homemade ruler with a strategic cutout or guiding markers could help if lack of visibility hinders the sewists practice.

Rulers 1 - 5

Corrugated cardboard is a similar thickness to a good quality ruler, which made it an obvious choice for a ruler base. Regarding the procedure, it was difficult to cut evenly through the layers of cardboard using a utility knife; while the scissors were more effective and cutting, it was difficult to cut around the template precisely. As for taping the corrugated cardboard, it was challenging to create smooth edges with either the masking tape or the packing tape. The former was not flexible enough to bend without fold lines and the latter stuck to itself easily and was difficult to manipulate. A common challenge with the both tape materials is that, unless one piece is used, there will be a slight bump caused by overlapping edges.

The papier-mâché did successfully cover the edge of cardboard, but similarly with the tape, multiple pieces of newspaper created edges that were not smooth. Overall, the ruler is sturdy and lightweight but the additional materials, procedure, and drying time does not indicate that this is an efficient option.

Rulers 6 and 7

The canvas was easy to cut out but the frayed edges, caused when severing the weave of the fabric, made it difficult to create a smooth edge. These frayed edges were exacerbated by the starch and modge podge solutions, and ultimately neither of these preparations created a stiff piece, so this time and resources required indicates this is not a viable option.

Further research

Based on this study, investigation into the material and or methods are warranted. Regarding the ruler’s base material. The selected base material should be easy to cut out and trim (and therefore trace). These could be papers of different weights or fabrics that do not fray, for example a double knit (for example double knits or a woven prepared with a row of stay stitches). Other materials like wood, or even 3D printed rulers, could be other options for DIY rulers and these materials could easily accommodate cutouts or indicators that would aid a sewist in seeing their fabric and lining up their curve.

Alternatively, more experimentation with the methods of preparation, including the cutting or trimming tools used, could be worthy of exploration if no alternative base materials are available.

Appendix

Figure 1: Scanned images of the lines created when the rulers were traced.

References

More Free Printable French Curves and Hip Curves by Leila at Grown Your Own Clothes.

Scientific Writing Guide from Acadia University.